2025 Hot Sale Cassava Processing Machines for Garri and Attieke Production Gari Processing Machine Attieke Processing Equipment

The Complete Production Process of the Attieke Production Line Attieke, a traditional West African food, is primarily made from cassava. It is fermented and steamed to form granules, bearing a resemblance to the taste of rice. In an attieke production line, the full production process includes cleaning, peeling, grating, fermentation, dehydration, granulation, and steaming. Cleaning Stage The initial step in the attieke production line is cleaning. Once harvested, cassava must be thoroughly cleaned to eliminate dirt and impurities on its surface. This ensures that the final product is of high quality and free from contaminants. Peeling Stage After cleaning, the cassava proceeds to the peeling stage. Peeling is crucial as it removes the toxic elements present in the cassava skin and enhances the overall quality of attieke. This step is essential for producing safe and palatable attieke. Grating Stage Following cleaning and peeling, the cassava undergoes a grating process. This transforms the cassava into pulp, which is more suitable for subsequent attieke production steps. The grated cassava pulp provides the base material for creating attieke. Fermentation Stage Fermentation is a pivotal stage in the attieke production line. To produce high - quality attieke with its characteristic flavor, the crushed cassava is fermented. This fermentation process imparts a unique taste and texture to the final product. Dehydration Stage After fermentation, the cassava pulp needs to be dehydrated. Dehydration is a key step in the attieke production line as it reduces the moisture content of the pulp, making it easier to handle and process further. Granulation and Steaming Stage Once the cassava pulp has been dehydrated and formed into cassava cakes, it is time for granulation. Granulation transforms the cassava cakes into attieke particles. Subsequently, these particles are steamed to achieve the desired texture for attieke production. Processing Equipment Used in the Attieke Production Line We have just described the complete production process of the attieke production line. Now, Henan Jinrui will introduce the processing equipment utilized in small and cost - effective attieke production lines. This includes dry sieves, paddle washers, peelers, graters, and hydraulic presses. Dry Sieve A dry sieve is an essential cassava cleaning device in the attieke production line. Harvested cassava is processed through dry sieve equipment to remove surface dirt and impurities. This ensures that only clean cassava proceeds to the next stages of production. Paddle Washer In the attieke production line, the paddle washer is the equipment required during the cleaning process. Henan Jinrui's paddle washers are designed with a counter - current washing mechanism, which results in a more efficient and thorough cleaning effect. This ensures that the cassava is impeccably clean before further processing. Peeler Selecting the right peeler is of utmost importance for a small and cost - effective attieke production line. A suitable peeler not only boosts the final yield of attieke but also ensures a superior peeling outcome. Henan Jinrui's peelers use sand rollers for peeling, minimizing the loss of cassava raw materials. Additionally, they offer a peeling rate of up to 90%. Grater For the grating process in the attieke production line, a grater is the necessary processing equipment. Henan Jinrui's graters employ licker - roller grating technology, enabling maximum grating of the cassava. This ensures that the cassava is processed into a fine pulp, ready for fermentation. Hydraulic Press In the attieke production line, a hydraulic press is used for dehydration. It operates on the hydraulic principle to extract the water from the cassava pulp. This efficient dehydration process is crucial for the overall production of attieke.

- Shipping:

Learn More

The cleaning part in fufu preparation with automatic processing facility:

Work flow in the cleaning part for fufu preparation:

Fresh cassava is fed through a dry sieve to remove weeds and other foreign matter and then sent to a paddle washer to wash off the sediment and accompanying stones. After that, the cleaned cassava is sent to the peeling machine to remove the inner and outer skins.

the cleaning part for fufu preparation

the cleaning part for fufu preparation

Main machines configured in the cleaning part:

Dry sieve--to remove the impurities and dirties like leaves, weeds, and mud attached on cassava roots

Paddle washer--to wash the primary cleaned cassava roots thoroughly.

Cassava peeler--to peel the poisonous cassava skins, ensuring the food safe and fufu taste.

The processing part in fufu preparation with automatic fufu processing facility:

Work flow in the processing part for fufu preparation

The peeled cassava is cut into small pieces by the cutting machine and then sent into the cassava grater to be beaten into fine cassava pulp, which is sent into the fermentation tank or ground pool for fermentation for about two days. This is the biggest difference from the traditional processing. Compared with fermentation after cutting, crushing into pulp and then fermentation can reduce the storage space and the difficulty of transporting to the next processing facility after fermentation. After fermentation, the cassava pulp is pumped into the plate frame filter press for dehydration by a screw pump to complete the entire processing section.

the processing part for fufu preparation

the processing part for fufu preparation

Main machines configured in the processing part:

Cassava cutter-- to cut cassava roots into small pieces

Cassava grater--to grate and grind the cut pieces into slurry

Plate-frame filter press--to dehydrate cassava slurry by squeezing the excessive moisture.

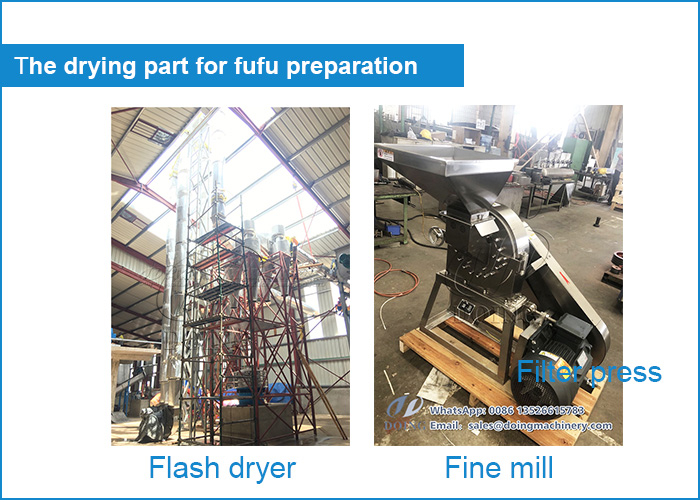

The drying part in fufu preparation with automatic fufu processing facility:

Work flow in the drying part for fufu preparation:

The dewatered fufu flour is crushed into powder by the powder cake crusher and then sent into the two-stage airflow dryer by the hoist for drying, the humidity is reduced to below 14%, and the finished product is crushed twice by the fine milling machine to ensure the quality of the finished product.

the drying part for fufu preparation

the drying part for fufu preparation

Main machines configured in the processing part:

Flash dryer--to dry wet fufu flour by adopting negative pressure drying principle.

Fine milling machine--to mill the dried fufu flour again so as to reach the fineness requirement.

All in all, fufu preparation with automatic fufu processing facility has become a common preparation method in modern fufu processing business. Henan Jinrui, as a professional supplier of fufu flour processing facility, can provide from one-ton-per hour to forty-tons-per-hour fufu flour processing line, which can also be designed into semi automatic and fully automatic types. If you want to know more about machines for fufu preparation, welcome to contact us!