Cassava processing facility peeler machine éplucheuse et laveuse de manioc Lavadora de Yuca

Cassava peeling machine, also called cassava peeler, is used for peeling the two layers of cassava.It is widely used in garri processing line and cassava flour processing line. In cassava peeling process, the cuticle part of cassava is removed because it will be helpful to improve the taste and quality of the cassava processing products.

- Shipping:

Learn More

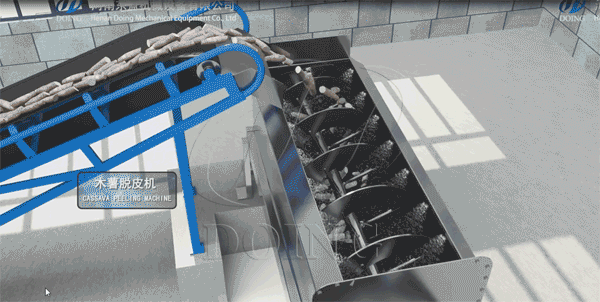

2. Working process of cassava peeling machine

The cassava peeling machine adopts the latest design of emery roller peeling, through the friction between the material and the emery roller to achieve the purpose of clean and thorough peeling, peeling rate can reach more than 95%.Emery roller peeling can peel cassava epidermis and the second layer of skin, so the surface of the material after peeling is smoother and the material loss is low. While the cassava is peeled, the conveyor screw drives the cassava to roll forward and transfer the peeled cassava to the next section. And the peels of cassava and other debris fall into collection tank.

Working process of cassava peeling machine

Working process of cassava peeling machine

3. Technical parameters:

| Model | Capacity(t/h) | Power(kw) | Dimension(mm) | Weight(kg) |

| DYTP-40 | 0.5-1 | 3 | 3250*1050*1100 | 1200 |

| DYTP-60 | 1-2 | 5.5 | 4250*1050*1100 | 2000 |

| DYTP-80 | 3-4 | 7.5 | 5250*1050*1100 | 3000 |

4. Structure of cassava peeling machine

Cassava peeling machine mainly composed of frame, upper cover, motor, reducer, brush roll, spraying system, transmission system, screw conveyor. And the parts which touch the material are all made of stainless steel material.

Frame and upper cover are basic structure of cassava peeling machine, the upper cover can be opened, but when working, it is normally closed to ensure cassava not be polluted.

Motor is used to provide power for cassava peeling mahcine. Reducer can control the running speed of cassava.

1) Emery roller: it is used to rub cassava to peel its gray peels and the 2mm thick cuticle part of cassava.

Different with cassava peeler equipped with plastic brush, stainless steel ring, nailing roller, it has the advantages of long service life, easy maintenance,stable running.

Emery roller

Emery roller

2) Transmission system and screw conveyor: Transmission system providing power and screw conveyor to transport peeled cassava forward. By adjusting the transmission speed, the cassava peeling effect can be adjusted. Doing Group can dispatch professional engineer for equipment debugging, to ensure better peeling effect.

3) Spraying system: to wash way cassava peels and meanwhile wash peeled cassava to ensure it is clean.

4) Discharging part: to discharge cassava peels and other debris