Cassava flour manufacturing machinery

The introduction of cassava flour manufacturing machinery which includes cassava cleaning machine, peeling machine, peeling machine, grating machine, dewatering machine, drying machine and filtering machine.

- Category: Cassava flour processing machine

- SKU: DY012

BUY NOW!

Description

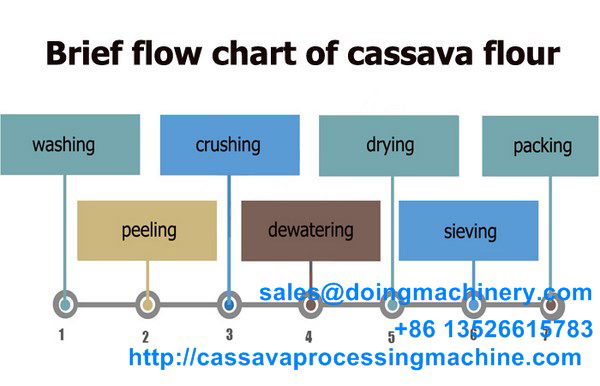

Cassava flour manufacturing process contains the following steps:

cassava cleaning-washing-peeling-grating-dewatering-drying-filtering-packing

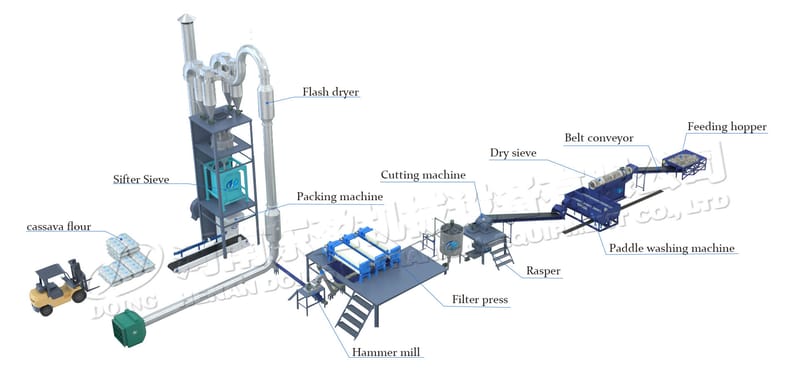

Accordingly, the cassava flour manufacturing machinery used in these process are the following:

Dry sieve-paddle washing machine-cassava peeling machine-rasper-plate frame filter press-flash dryer-viberation sieve

1.Cassava cleaning machine-dry sieve

This cassava flour manufacturing machinery is used in the first step for the cleaning of the sand,small stones and other debris of the cassava. The main features of this machine is the multiple inner spiral design and the stable running speed.

2.Cassava washing machine-paddle washing machine

The working principle of DOING paddle washing machine is the countercurrent washing. Due to the different move direction of the cassava and water, the washing effect is improved greatly. This is a easy operating and low water consumption machine.

The purpose of this cassava flour manufacturing machinery is to remove the outer peels and subcutaneous epidermis pf cassava root. The is a high efficient machine whose a peeling rate is above 95%.

4.Cassava grating machine-rasper

This is another important cassava flour manufacturing machinery because it can determine the cassava flour yield. Designed with bidirection rasper, this machine can fully break the cassva and achieve high grating rate and high extraction rate.

5.Cassava dewatering machine-plate frame filter press

The plate frame filter machine is a effective dewatering machine which utilizes the press to realize the solid-liquid separation. The main advantages of this machine is its high degree of automation which means it can achieve automatic pressing, filtering, draining, squeezing, loosing and so on.

6.Cassava drying machine

6.Cassava drying machine

After dewatering process, the cassava flour need to be dryed in the drying machine to reduce the water content in cassava flour. This widely used cassava flour manufacturing machine for this process is flash dryer which takes advantage of the high speed hot air to dry the cassava flour. Due to the high heat-exchange rate, this process is completed in seconds.

7.Cassava filtering machine-viberation sieve

This process is to filter the cassava flour to meet higher production standard.By separating out the large particles of cassava flour, the cassava flour is finer.

Doing Company is a professional cassava flour manufacturing machinery manufacturer. If you are interested about these machine, welcome to contact us.

Inquiry: http://services.doinggroup.com.cn/kf.php?mod=client&cid=doingequipment&wid=23

Click here to give you the best price

Welcome to make an inquiry of our machine by following contacts:

Contact: Ms Elina

Email: sales@doingmachinery.com

Tel: 0086 371 5677 1822

Whatsapp/Phone:0086 135 2661 5783

View more:

http://www.cassavaprocessingplant.com

cassavaprocessingmachine