Cassava starch production process

cassava starch production process

- Category: cassava starch processing machinery

BUY NOW!

Description

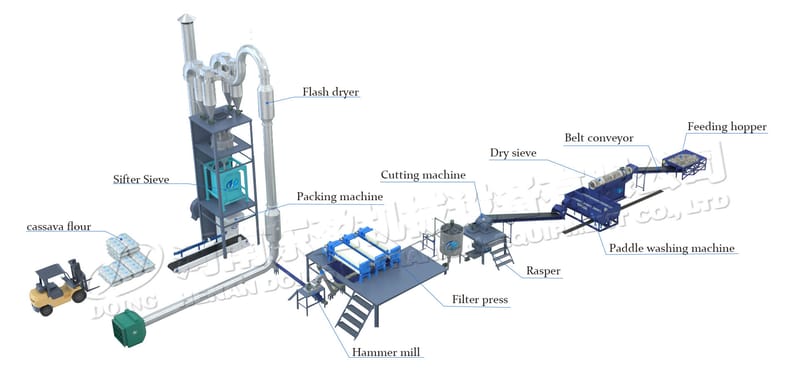

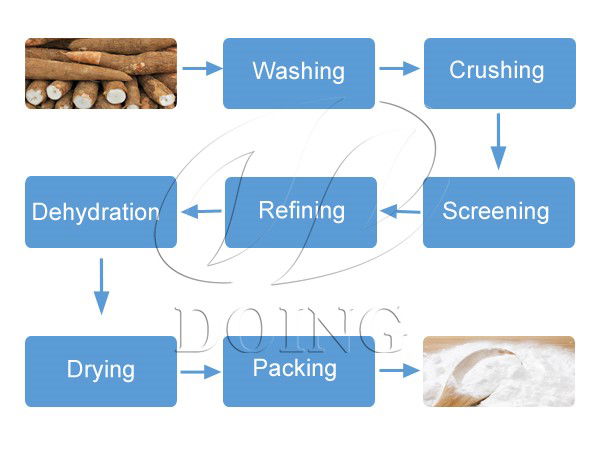

The entire cassava starch production process can be divided into the following section:

Pretreatment of raw material-extraction of cassava starch-separating and desanding of cassava starch-concentration and refining of cassava starch-cassava starch dewatering-cassava starch drying and packing

Cassava starch production process

Here is the detail introduction of cassava starch production process

1. Dyr sieve for cassava cleaning: Dry sieve is the widely used cassava starch processing machine for cleaning process in cassava starch production line. It has the features of dry sieve is simple structure, reasonable speed and no damage to material.

2. Paddle washing machine: Incassava starch production process, washing serves to remove the outer skin of the root as well as the adhering dirt. It features with large capacity, low water consumption and good washing effect.

3. Grating: This is the most important process for cassava starch production process for it determines the starch yield. Rasper is a high efficient cassava grating machine with a cassava breaking rate more than 94%. Doing Company rasper is designed and manufactured on the basis of international advanced technology.

Cassava grating machine

4.Centrifugal filtering: Another main factor which influence the extraction rate in cassava starch production process is the filtering process. The centrifuge sieve and fine fiber sieve are adopted for this process. And the high efficiency of these machine makes it feasible to utilize high quality sieve plates made of stainless steel, which will withstand abrasion and CIP-chemicals.

5.Desanding: The specific gravity of mud and sand is greater than that of water, and is also larger than that of starch granules. Hence the separation of sand out of starch slurry by gravity separation is effective. Desander is a machine serves for this purpose in cassava starch production process.

Centrifugal sieve

6. Concentration and refining of cassava starch

Hydrocyclone station is the widely used machine in cassava starch production process for starch refining, washing and recycling. This cassava starch processing machine can effectively separate non-starch substances such as protein, fiber and cell sap in starch.

7.Dehydrating: Due to the starch milk contains a lot of water, it must be dehydrated for cassava starch production process. At present, peeler centrifuge is often used for dewatering. The moisture content of wet starch is required to be 38% lower after dehydration.

8. Cassava drying section

In cassava starch production process, cassava starch drying is done by starch flash dryer. The water in wet cassava flour evaporate by high speed hot air flow to desired quality.

Peeler centrifuge

The project details of cassava starch production process:

1.Plant: this project covers an area of about 400 square, the plant generally is not small than 1,000-square

2.Power: 380 volts, 3 phases, 50 Hertz, the largest floating voltage 6% and 4% of the maximum frequency of floating.

3.The installed capacity is about 180KW. The actual consumption is about 150KW

4.Water: The extraction Section 15-20 cubic / hour, in line with the drinking water standard. Section 10 cubic cleansing / hour, it can be part of the cycle and also be used for later water. (User-owned boiler)the burning stove can also be used in plant.

Chat on line / Whatsapp/Phone:+86 135 2661 5783

Email: market@doinggroup.com

Tel: 0086 371 5677 1822

View more:

cost of cassava processing equipment

cassava starch extraction machine

cassava starch production in Ghana

how to extract cassava starch

cassava peeling machine in Ghana