How to extract cassava starch ?

Description

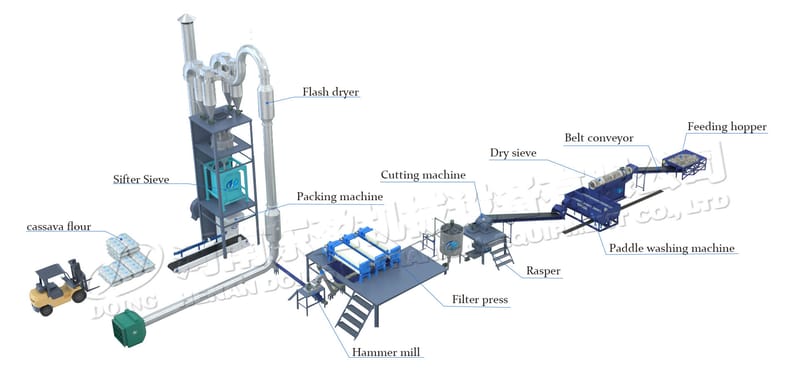

The brief introduction of the process of how to extract cassava starch

Firstly, the fresh cassava is cleaned and mixed, then transported to a special rasper and fully pulverized to a state of free starch, washed and separated into pulp, and the starch in the slag is completely separated after multi-stage washing. Next, the separated pure pulp passes through several grades of starch separation and protein purification hydrocyclone units for production of starch from cassava, then dehydration into the peeler centrifuge, trying to make the water separated by about 38% and then evenly fed into the flash dryer to dry the safe water 13-14%. finally, the finished product packed into 25, 50KG for the warehouse.

Cassava starch processing plant

Step 1: Raw material transportation and cleaning

The harvested cassava is firstly transported to the storage ground in how to extract cassava starch. Then it is transported by belt conveyor to the dry sieve to remove stone, weeds, leaves and other debris of cassava.

Step 2: Cassava washing

Together with cleaning, washing has an important influence on the subsequent how to extract cassava starch. Therefore it is required to clean and wash cassava thoroughly to guarantee high quality starch.

Step 3: Cassava grinding

In the how to extract cassava starch, it is vital to release as much as free starch from cassava roots as possible. Rasper is the widely used cassava starch processing machine whose main function is to destroy the structure of the cassava, so that the tiny starch granules can be released from the roots of the cassava.

Cassava grating machine

Step 4: Separation: In the links of how to extract cassava starch, the most significant impact on the extraction rate of starch is grating, screening and refining process. Centrifuge sieve is used for separation process whose main function is to remove fibers out of starch slurry. This cassava starch processing machine features with high precision dynamic balance, stainless steel screen and high efficiency.

Step 5: Desanding: The starch slurry is pumped into desander to remove sand impurities to improve starch taste in desanding stage of how to extract cassava starch.

Step 6: Concentration and refining

In how to extract cassava starch, protein and other organic and inorganic impurities need to be removed by hydrocyclone station in how to extract cassava starch. Doing Company adopts 18 stage cyclone group for three purpose: concentrating, refining and recycling. The whiteness of cassava starch is guaranteed in this step.

Cassava starch drying machine

Step 7: Starch dehydration

Starch milk is dehydrated to a moisture content of below 40% for how to extract cassava starch.

Step 8: Drying and packing

The drying step follows dehydrating to dry starch to the desired quality. By adopting negative pressure drying, the whole process is completed in seconds in how to extract cassava starch. And this flash dryer is also equipped with cooling system to ensure the moisture uniformity of cassava starch.

Chat on line / Whatsapp/Phone:+86 135 2661 5783

Contact: Ms Elina

Email: market@doingmachinery.com

Tel: 0086 371 5677 1822

View more:

small scale cassava starch processing plant

cassava starch production process

tapioca starch processing machine

cassava starch extraction machine

tapioca starch manufacturing process