How to make tapioca flour from cassava?

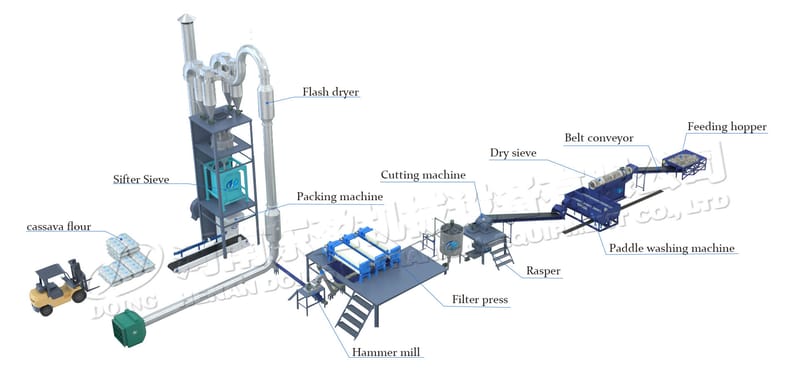

Introduction of process for how to make tapioca flour from cassava.The whole process includes choosing, Cleaning, Washing, Crushing, Separating, Enrichment and purification, Dewatering, Drying and packing

- Category: cassava starch processing machinery

BUY NOW!

Description

The following is the procedure for how to make tapioca flour from cassava

Cassava choosing-cleaning-washing-grinding-separating-concentation and refining-dewatering-drying and packing

Unit 1. Choosing: In the processing of how to make tapioca flour from cassava it is vital to complete the whole process within the shortest time possible, since as soon as the roots have been dug up, as well as during each of the subsequent stages of manufacture, enzymatic processes are apt to develop with a deteriorating effect on the quality of the end product.

Cassava cleaning machine

Unit 2. Cleaning: The newly harvested cassava roots contains weed, stone, siol, sand and other debris. Therefore they need to be cleaned first before further processing in cassava starch production line. Dry sieve is the most widely used cleaning machine in how to make tapioca flour from cassava.

Unit 3. Washing: The washing process for how to make tapioca flour from cassava is used for removing the attached soil, sand, dirt and so on with paddle washing machine and wahsing water.

Unit 4. Crushing: The cassava root need to be crushed into slurry in order to release its starch from cell wall. Rasper is the machine used for how to make tapioca flour from cassava. DOING rasper introduces the advanced international technology which can achieve a high crushing rate and high starch extraction rate.

Cassava crushing machine

Unit 5. Separating: The cassava slurry contains many impurities, such as fiber, protein and cell sap. They need to be separated from starch. Centrifuge sieve and fine fiber sieve are the cassava starch processing machine serves for separating fiber from starch for how to make tapioca flour from cassava.

Unit 6. Enrichment and purification: This process is used for removing protein, cell sap and other impurities out of cassava slurry. In how to make tapioca flour from cassava, hydrocyclone station is the extensively used machine for this process. DOING full hydrocyclone technology can achieve the enrichment, purification and recycling of starch which not only ensures the high quality of final cassava starch but also prevent the waste of cassava starch in processing.

Unit 7. Dewatering: The dewatering process is maily for reducing water content of cassava milk so that it can meet the drying standard in how to make tapioca flour from cassava. We usually use peeler centrifuge to dewater cassava milk. This machine can shorten dewatering time and increase production capacity by 50%. This is required that the water content of cassava starch is about 38%-40%.

Cassava starch dewatering machine

Unit 8. Drying and packing: This is the final processing procedure in how to make tapioca flour from cassava. The dewatered cassava starch enters into flash dryer by feed conveyor and mixs with the high speed hot air flow, and the drying process is completed in just a few seconds by heat exchange. After that, the dryed cassava starch are packed into 25kg or 50kg according to different requirements.

Doing Company is a professional cassava deep processing equipment manufacturer. Our engineer can provide professional guide about how to build a how to make tapioca flour from cassava, welcome to contact us.

Click here to give you the best price

Contact us(inquiry)

Whatsapp

Welcome to make an inquiry of our machine by following contacts:

Contact: Ms Elina

Email: market@doingmachinery.com

Tel: 0086 371 5677 1822

Whatsapp/Phone:0086 135 2661 5783

View more:

http://www.starchprojectsolution.com

cassava starch machine