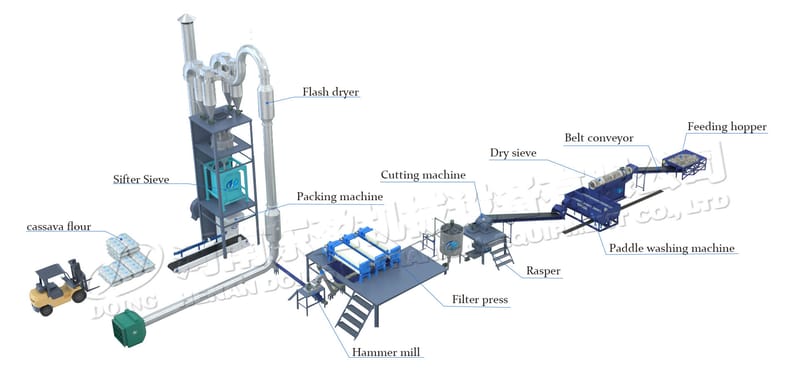

Industrial cassava starch production line

Cassava starch production line process cassava into starch through cleaning, washing, grating, slag and slurry separation to starch slurry dewatering and drying.

- Category: cassava starch processing machinery

- SKU: DY059

BUY NOW!

Description

In cassava starch production line, we use physical separation method to process cassava starch. By taking use of the property that cassava starch is insoluble in cold water and has a specific gravity greater than water, Doing Company use water and professional cassava starch processing equipment to separate the starch from the water suspension to achieve the purpose of recovering the starch.

Cassava starch production line

1. Cleaning and washing section: Coarsely cleaning of cassavaes takes place during the transport of cassavaes to the scrubber by channel in cassava starch production line. The main cleaning is conducted in dry sieve. The stones, sludge and light wastes are removed at this step. Then the cassava is transported into paddle washing machine for removing the remaining sand, dirt, soil and other debris. Water used for washing is then purified and recycled back into the process.

2. cassava crushing section: Crushing takes place after washing and is sometimes applied to whole tubers. And the crushing serves to break cassava structure and release starch from cassava cell. In cassava starch production line, from cassava cleaning and conveying to the crushing process, it is a continuous operation. After the crushing, the slurry is sent to the downstream process by the transfer pump.

3. Separation section: This process is mainly used to separate fiber from starch. It is required that the starch residue contains less than 35% starch after separation process in cassava starch production line, wherein the free starch contains less than 5%, and the fiber impurity content of the milk slurry is less than 0.05% in small scale cassava starch processing plant.

Cassava grater

4. Starch desanding section: In cassava starch production line, this process is used for removing sand out of cassava slurry. And the principle is specific gravity separation. After sand removal, not only impurities such as fine sand are removed but also disc separator can be protected.

5. Concentration and refining: After desanding, the starch slurry is injected into the hydrocyclon station through the starch pump for concentration and refining. In cassava starch production line, hydrocyclone station is widely used for this purpose. Starch slurry firstly goes from concentration stage, to refining and finally to recovering stage. And the protein, fibers and cell sap are basically removed.

6. Dehydrating unit: In cassava starch production line, dehydrating is used to reduce the water content to facilitate drying for cassava starch production line. tapioca starch processing machine used for starch dewatering has the characteristic of stable operation, good dewatering effect and automatic discharging.

Cassava starch separation machine

7. Drying: Flash dryer is extensively used in cassava starch production line which can effectively dry wet starch to low moisture content by negative pressure dying system. Instantaneous drying system ensures high efficiency and moisture uniformity of starch.

Chat on line / Whatsapp/Phone:+86 135 2661 5783

Email: market@doinggroup.com

Tel: 0086 371 5677 1822

View more:

cassava starch production process

cassava starch processing machine

cassava starch extraction machine

cassava starch production in Ghana

how starch is made from cassava

cassava starch extraction process