Industrial potato starch machine

Introduction of Industrial potato starch machine.

- Category: Potato starch processing machinery

- SKU: DY001

BUY NOW!

Description

Doing Company is a professional potato starch machinery supplier who has years of experience of designing and manufacturing machine for large, medium and small size plant.

The following is the introduction of our production technology and main potato starch machine

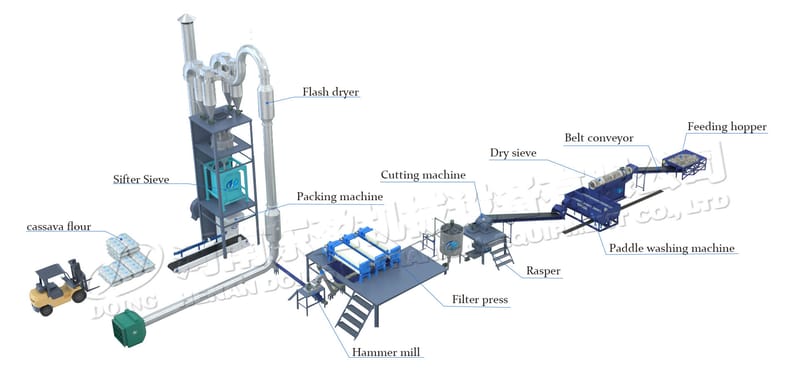

Cleaning and washing-cutting and rasping-separating-concentration and refining-dehydrating-drying and packing

Potato starch machine

1.Cleaning and washing machine: The widely used potato starch machine for cleaning is dry sieve. It mainly removes the sand, weed, small stones and other debris of potato. After cleaning, materials are transported into potato washing unit. Rotary washing machine is a widely used washing machine. It can effectively avoid the breaking of potatoes in the washing process, so the starch in potatoes can be retained to the maximum extent and the utilization rate is higher.

2. Crushing machine: Then crushing process is the most important procedure in potato starch production line for it determines the starch extraction rate of end products. The high efficient potato starch machine with higher extraction rate produces more potato starch. DOING rasper is high efficient machine which can completely release starch granules in potato cells, and ensure the binding starch content in the potato cell to a minimum.

3. Separating and desanding machine: After crushing, the fiber, protein, cell sap and other materials are released from cell wall. Therefore the separating is needed to separate starch from fiber and other impurities. Separating process mainly remove fiber from starch. And the mainly used potato starch machine is centrifuge sieve whose function is remove fibers out of starch slurry. After that, the potato starch slurry is pumped by a screw pump into a desander to remove sand particles in potato starch processing plant.

Potato starch separating machine

4.Concentration and refining machine: Hydrocyclone station is also an important potato starch machine. It is mainly used for the concentration and refining of starch milk. Meanwhile, it can remove the protein and cell sap which can further improve the starch quality.

5.Dewatering machine: Vacuum filter is a extensively used potato starch machine for dewatering which is mainly for reducing the water content of starch milk. After dewatering, the water content in starch milk is 38%-40%. DOING vacuum filter can achieve continuous automatic production, which ensures a cleaning production environment.

Potato starch dewatering machine

6. Drying and packaging machine: The purpose of this section is to dry the dehydrated starch to the desired moisture content to meet market standard. Flah dryer is the used potato starch machine. The air is heated to the required temperature through the filter net through the heat exchanger, and the hot air is sucked into the flash dryer by the fan. Then the high speed hot air mixes with the wet starch and dry the starch by heat exchange. The air and starch are separated in the cyclone separation device. The air is discharged out of the machine while the starch is transported into the packing machine. Then the final potato starch is packed by semi-automatic machine for storage.

Click here to give you the best price

Chat on line(inquiry)

Whatsapp

Welcome to make an inquiry of our machine by following contacts:

Contact: Ms Elina

Email: market@doinggroup.com

Tel: 0086 371 5677 1822

Whatsapp/Phone:+86 135 2661 5783

View more:

http://www.starchprojectsolution.com

cassava starch machine