Sweet Potato Starch Equipment Sweet Potato Starch extraction machine

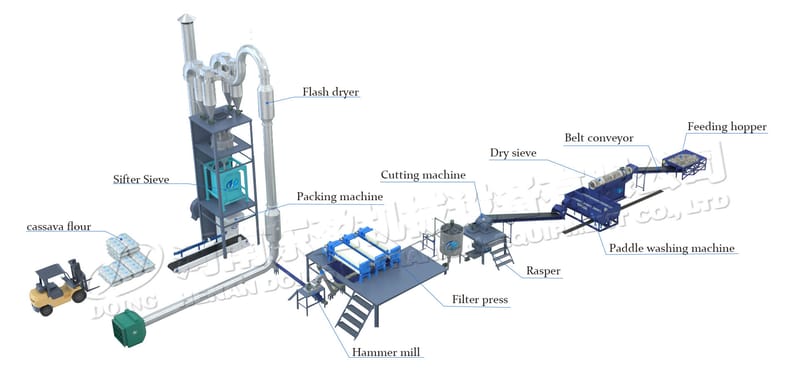

The whole process of how to extract starch from sweet potato includes sweet potato washing and cleaning, sweet potato cutting, sweet potato crushing, starch slurry purifying and concentration, starch dewatering, starch drying, starch sieving and packing.

- Category: Sweet potato starch processing machinery

BUY NOW!

Description

Section 1. sweet potato washing and cleaning

sweet potato will be transported to dry sieve, sweet potato will cleaned by this machine. The machine will rotate its spirals to clean sweet potato and remove some peels of sweet potato. Then the sweet potato will be transported by water conservancy conveyer. Then the rotary washing machine will wash the raw material. The machine adopts counter-current washing principle, so sweet potato can flow in opposite direction against water, which can make the washing effectively.

Section 2. sweet potato cutting and crushing

Sweet potato cutting machine is usually applied in the processing line, however it is also not used in the processing line. The machine can cut the sweet potato into some pieces, which can help relive the burden of rasper. After cutting the sweet potato, then rasper will crush them into a kind of mush. Compared with other rasping machine, the rasping machine has high crushing coefficient. The machine plays a key part in the process of how to extract starch from sweet potato.

Rasper used for sweet potato crushing

Section 3. sweet potato starch slurry extraction

After being a kind of mush, the sweet potato starch slurry will go through several steps. In the process of how to extract starch from sweet potato, the extraction part is very significant. First, centrifuge sieve is one of machines for extraction of starch from sweet potato. The machine has fine screen mesh, which can screen fiber from starch slurry. Then fine fiber sieve will remove some fiber out of sweet potato starch slurry. After that, Disc centrifuge will remove some fiber left and cell liquid and so on. It is a kind settling centrifuge, which is usually matched with hydrocyclone unit. So the machine can be used for enrichment and purification of starch slurry. Then the last step of this section is to concentrate, recover and wash the starch slurry. The machine consists of many parts, therefore, the starch slurry will become purer at this time.

Fine fiber sieve

Section 4. sweet potato starch slurry dewatering

The section is done by vacuum dewatering machine. The machine is used for starch dehydration. The rotating drum speed can be controlled, and it is equipped with reciprocating paddle stirrer to prevent starch deposition. And the machine dewater starch with high efficiency.

Section 5. sweet potato starch drying

After dewatering, the sweet potato starch still contain 38% water moisture. So it must be dried by flash dryer. The flash dryer has high efficiency. It adopts negative pressure system and cooling system, so it can dry the sweet starch in a short time. In the process of how to extract starch from sweet potato, flash dryer also plays a key part.

Sweet potato starch sieving machine

Section 6. sweet potato starch sieving and packing

Sweet potato starch at this time still contains some big size sweet potato starch, so it must be sieved by starch sieving machine. The fine degree of the starch can be guaranteed. Then the final starch will be packed by automatic sieving machine.

This is the whole process of how to extract starch from sweet potato. And the main machines in the processing line are designed with advanced technology, so the quality is worth guaranteeing. Doing Company located in China, we have been completed several starch processing plant project worldwide, also include the sweet potato starch production plant, we insist to develop our technology and machine design for how to extract starch from sweet potato, we are your best choice to start your sweet potato starch production business.