Sweet potato starch production line

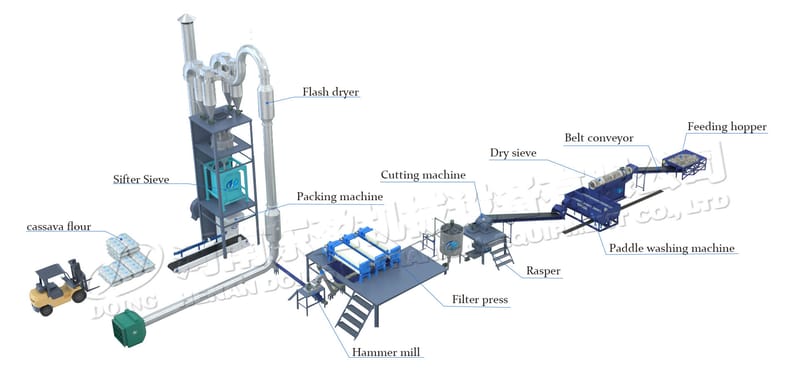

Introduction of sweet potato starch production line. The whhole sweet potato starch production line includes: choosing and weighting, cleaning and washing, cutting and crushing, separating, concentration and refining, dewatering, drying and packing

- Category: Sweet potato starch processing machinery

BUY NOW!

Description

A entire sweet potato starch production line is composed of the following process:

Choosing and weighting-cleaning and washing-cutting and crushing-separating-concentration and refining-dewatering-drying and packing

1.Choosing and weighting of sweet potato: Before cleaning the sweet potato, it is important to choose good raw material. Different sweet potato contains different starch content, it will be better to choose fresh and high-quality sweet potato. Then the chosen sweet potatoes are weighed and stored in a sweet potato stack. After that,they are transported by a conveyor to a cleaning machine in sweet potato starch production line.

Sweet potato cleaning machine

2. Cleaning and washing: The sweet potato is firstly be cleaned in dry sieve to remove the sand, weed and other dirty materials in sweet potato starch production line. The dry sieve is a high effective washing machine which will not damage the raw material for isolation of starch from sweet potato. And the washed sweet potato is transported into rotary washing machine to further wash the attached impurities, such as soil and sand. This washing machine adopts countercurrent washing principle which can ensure the raw material be washed cleanly and thoroughly.

3.Cutting and crushing: After cleaning and washing process, the sweet potato is converted to the sweet potato starch processing machine for cutting. The main purpose of cutting in sweet potato starch production line is to make the crushing easier. By cutting the sweet potato into small pieces, it not only make the crushing more thoroughly but also reduce the possible damage caused to the rasper machine. After cutting, the broken pieces goes into the crushing machine. The extensively used crushing machine is rasper. As an important sweet potato starch machine, DOING rasper adopts Sweden SKF and Germany Optibelt technology which offers high crushing efficiency and longer service life.

Sweet potato crushing machine

4. Separating: The crushed sweet potato paste contains other impurities like fiber, protein and cell sap. Therefore the separating process is needed. It also has an important influence on the starch yield. In sweet potato starch production line, we use centrifuge sieve for separating fiber out of starch.

5. Concentration and refining: After the separation section, the sweet potato slurry need to be further refined. This process mainly removes the protein, fine fiber and cell sap. In sweet potato starch production line, the mainly used machine for the extraction of starch from sweet potato is hydrocyclone station. A full hydrocyclone technology includes the concentration, refining and recycling.

Sweet potato starch refining machine

6.Dewatering: Even after the concentration, the water content in the starch milk in still high. The vacuum filter is used for the dehydration of the starch milk in sweet potato starch production line. The vacuum filter is a continuous running sweet potato starch machine which using the moving filter cloth as the filter medium and using the negative pressure and gravity provided to separate the solid from liquid. After the dewatering process, the water content of the starch should below 40%.

7.Drying and packing section: The dehydrated starch is then transported into flash dryer for drying in sweet potato starch production line. The flash dryer takes use of negative pressure principle which effectively controls the loss of the starch and ensures cleaning operation environment.

Click here to give you the best price

Contact us(inquiry)

Whatsapp

Welcome to make an inquiry of our machine by following contacts:

Contact: Ms Elina

Email: market@doinggroup.com

Tel: 0086 371 5677 1822

Whatsapp/Phone:0086 135 2661 5783

View more:

http://www.starchprojectsolution.com

cassava starch machine